ODM Chaw tsim tshuaj paus Tuam Tshoj PC PMMA Hollow Tshooj Phaj Extrusion Kab

Peb cov khoom tau lees paub dav thiab txhim khu kev qha los ntawm cov neeg siv khoom thiab tuaj yeem ua tau raws li qhov xav tau ntawm kev hloov pauv nyiaj txiag thiab kev sib raug zoo ntawm ODM Chaw Muag Khoom Tuam Tshoj PC PMMA Hollow Section Phaj Extrusion Kab, Peb ib txwm muab cov khoom zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws rau feem coob ntawm cov neeg siv khoom thiab cov neeg lag luam. Zoo siab txais tos tuaj koom nrog peb, cia peb tsim kho tshiab ua ke, thiab ya npau suav.

Peb cov khoom tau lees paub dav thiab ntseeg tau los ntawm cov neeg siv khoom thiab tuaj yeem ua tau raws li kev hloov pauv nyiaj txiag thiab kev xav tau ntawm kev sib raug zooTuam Tshoj PC Hollow Tshooj Phaj Extrusion Kab, PC Hollow Section Phaj Manufacturing Tshuab, Peb lub hom phiaj yog "kom muab cov khoom thawj kauj ruam thiab cov kev pabcuam zoo tshaj plaws rau peb cov neeg siv khoom, yog li peb paub tseeb tias koj yuav tsum muaj txiaj ntsig zoo los ntawm kev koom tes nrog peb". Yog tias koj txaus siab rau ib qho ntawm peb cov kev daws teeb meem lossis xav tham txog kev txiav txim siab, nco ntsoov tiv tauj peb. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog cov neeg siv khoom tshiab thoob ntiaj teb nyob rau yav tom ntej.

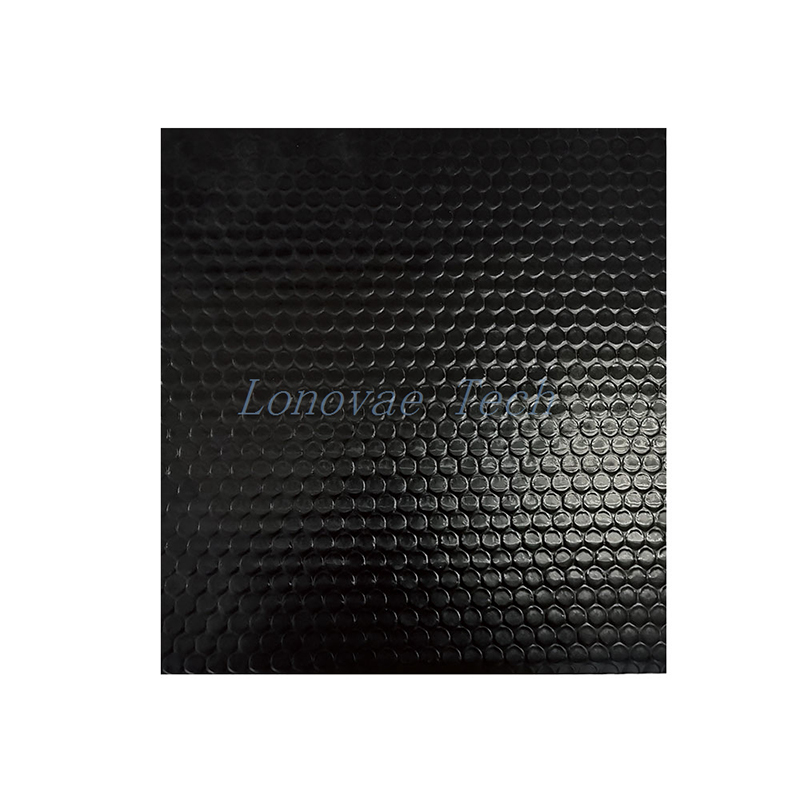

| Khoom npe | Tsheb PP Cellular Board |

| Thickness | 3mm-5mm; 8 hli; 10 hli |

| Dav | ≤1.4m |

| gsm ua | 2200-2500g; 2800-3000g |

| xim | dub |

| khoom | pp |

| daim ntawv thov | tsheb pem teb; rooj zaum; log tsheb cover etc. |

Cov txheej txheem nruab nrab ntawm PP honeycomb vaj huam sib luag txais yuav cov qauv honeycomb, thiab lub qhov txuas ncaj qha nruj nreem. Piv nrog rau cov qauv kab ntsug ntawm cov hollow vaj huam sib luag zoo tib yam, PP honeycomb vaj huam sib luag yog ib qho kev ntxhov siab nyob rau hauv 360 degree kev taw qhia, thiab muaj kev cuam tshuam thiab khoov tsis kam. Zoo heev, kev lag luam kev cia siab yog dav, vim hais tias lub vaj huam sib luag honeycomb muaj zog load-bearing muaj peev xwm thiab zoo heev cargo tiv thaiv muaj peev xwm, thiab lub lag luam prospect yog dav. Vim hais tias lub vaj huam sib luag honeycomb muaj zog load-bearing muaj peev xwm thiab cov cargo kev tiv thaiv muaj peev xwm ua tau zoo, nws yuav sai sai hloov cov hollow panels. . Edge banding thev naus laus zis tso cai rau lub peev xwm ntawm honeycomb panels yuav tsum tau tapping ntau dua, ua kom yooj yim rau cov neeg siv khoom ntxuav thaum siv thiab siv sijhawm ntev dua.

Nws yog kev ua haujlwm siab thiab tiaj tus.

1. Lub teeb nyhav

Qhov hnyav dua tuaj yeem txo lub nra ntawm lub tsheb thauj khoom. Nws tuaj yeem txo tus nqi thiab lub sijhawm thauj khoom.

2.Kev cuam tshuam zoo

Kev cuam tshuam muaj zog tuaj yeem nqus tau qhov corrosion thiab tuaj yeem txo qhov kev puas tsuaj ntawm sab nrauv.

3.Zoo flatness

Qhov saum npoo muaj zoo flatness thiab muaj xim ci.

Nws yog noo noo-tiv thaiv, tsis-corrosion thiab tuaj yeem ua rau hnyav dua.

Zoo Shock Resistance. Impact Resistance

PP cellular board nqus lub zog sab nraud thiab txo qhov kev puas tsuaj vim kev sib tsoo.

Lub teeb qhov siab

PP celluar board muaj lub teeb qhov siab thiab qis qis ntawm kev thauj mus los kom ceev cov thauj mus los thiab txo tus nqi.

Lub suab rwb thaiv tsev zoo PP celluar board tuaj yeem txo qhov nrov nrov nrov.

Zoo heev Thermal rwb thaiv tsev

PP celluar board tuaj yeem tiv thaiv tshav kub zoo heev thiab tuaj yeem tiv thaiv kom tsis txhob muaj cua sov.

Muaj zog dej-pov thawj. Corrosion Resistance

Nws tuaj yeem siv rau qhov chaw noo thiab corrosive rau lub sijhawm ntev.

Peb siv cov khoom tshiab zoo los tsim thiab tuaj yeem ua tau raws li ntau hom kev xav tau rau peb cov neeg siv khoom.

PP cellular board rau tsheb yuav siv tau rau ntau yam ntawm cov khoom, xws li lub rooj zaum rov qab thiab parcel txee thiab log tsheb npog thiab lwm yam.Nws yog lub teeb yuag thiab tsis muaj ntxhiab tsw phem.

Nws yog dav siv hauv yachts, tsheb, tsheb ciav hlau thiab lwm yam kev thauj mus los ntawm lub plhaub, qab nthab, muab faib, lawj, pem teb thiab lwm yam kev siv kho kom zoo nkauj sab hauv.

Txhawm rau kom muaj kev nyab xeeb ntawm koj cov khoom zoo dua, kev tshaj lij, ib puag ncig tus phooj ywg, kev pabcuam ntim tau yooj yim thiab ua tau zoo.

Peb cov khoom tau lees paub dav thiab txhim khu kev qha los ntawm cov neeg siv khoom thiab tuaj yeem ua tau raws li qhov xav tau ntawm kev hloov pauv nyiaj txiag thiab kev sib raug zoo ntawm ODM Chaw Muag Khoom Tuam Tshoj PC PMMA Hollow Section Phaj Extrusion Kab, Peb ib txwm muab cov khoom zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws rau feem coob ntawm cov neeg siv khoom thiab cov neeg lag luam. Zoo siab txais tos tuaj koom nrog peb, cia peb tsim kho tshiab ua ke, thiab ya npau suav.

ODM tus neeg muag khoomTuam Tshoj PC Hollow Tshooj Phaj Extrusion Kab, PC Hollow Section Phaj Manufacturing Tshuab, Peb lub hom phiaj yog "kom muab cov khoom thawj kauj ruam thiab cov kev pabcuam zoo tshaj plaws rau peb cov neeg siv khoom, yog li peb paub tseeb tias koj yuav tsum muaj txiaj ntsig zoo los ntawm kev koom tes nrog peb". Yog tias koj txaus siab rau ib qho ntawm peb cov kev daws teeb meem lossis xav tham txog kev txiav txim siab, nco ntsoov tiv tauj peb. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog cov neeg siv khoom tshiab thoob ntiaj teb nyob rau yav tom ntej.